- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: China

- Brand Name: yilida

- Model Number: TL-900

Elida brand functional film sealing machine technical parameters:

Power supply: 220V/50Hz/520W;

Sealing width: 5-14mm adjustable range;

Sealing material: thick 0.03-0.80mm thermoplastic film;

Sealing length: 0- infinity;

Bag sealing capacity: 55 bags / min (100mm);

Sealing speed: 0-12m/min (M / min);

Conveyor belt size: 775 x 140mm;

Temperature control mode: thermocouple type precision temperature control;

Temperature range: 0-300 degrees celsius;

Cooling: air cooling;

Conveying load: <5kg;

Exterior dimension: 810 * 370 * 310mm;

Printed words: less than 39 words (4 Pt);

Weight: 17.5kg.

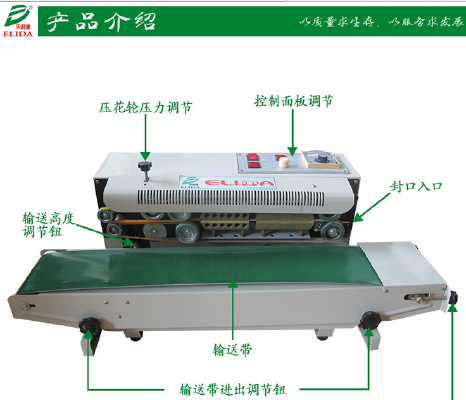

Elida brand functional film sealing machine principle structure:

1, the machine consists of frame, speed reducer drive mechanism, cooling mechanism of heating, sealing and printing mechanism, conveying device and electronic control system components;

2, switch on the power, the organization began to work. Electric heating element is energized after heating, the heating block and rapid heating control system to adjust to the desired temperature; pressure wheel rotation; according to the needs of the cooling system on cooling; conveyor belt transfer, and by the speed control device can be adjusted to a desired speed;

3, when equipped with the packaging of goods placed on the conveyor belt, sealing parts are automatically sent to the two bags in the operation of sealing tape and into the heating zone, heat sealing block through the belt transmission to the sealing part of the bag, the thin film heating molten soft, then through the cooling zone, the film surface temperature properly decreased then after a knurled wheel (or wheel rolling), so the sealing part on the plastic film sticking and pressing a reticulated pattern (or printed logo), and then by the guide rubber belt and conveyor belt will be sent packing bag sealed, complete sealing operation.

Elida brand functional film sealing machine maintenance:

1, after the use of the machine to deal with dust on the equipment;

2, in the first time after the closure of the temperature control switch is closed to allow the machine to run 3-5 minutes, so that it helps to protect the sealing bag in the heating temperature stay and reduce the service life;

3, ELIDA plastic bag sealing machine every 6 months or so on the drive gear lubrication oil.

- Place of Origin: China

- Brand Name: yilida

- Model Number: TL-900

Elida brand functional film sealing machine technical parameters:

Power supply: 220V/50Hz/520W;

Sealing width: 5-14mm adjustable range;

Sealing material: thick 0.03-0.80mm thermoplastic film;

Sealing length: 0- infinity;

Bag sealing capacity: 55 bags / min (100mm);

Sealing speed: 0-12m/min (M / min);

Conveyor belt size: 775 x 140mm;

Temperature control mode: thermocouple type precision temperature control;

Temperature range: 0-300 degrees celsius;

Cooling: air cooling;

Conveying load: <5kg;

Exterior dimension: 810 * 370 * 310mm;

Printed words: less than 39 words (4 Pt);

Weight: 17.5kg.

Elida brand functional film sealing machine principle structure:

1, the machine consists of frame, speed reducer drive mechanism, cooling mechanism of heating, sealing and printing mechanism, conveying device and electronic control system components;

2, switch on the power, the organization began to work. Electric heating element is energized after heating, the heating block and rapid heating control system to adjust to the desired temperature; pressure wheel rotation; according to the needs of the cooling system on cooling; conveyor belt transfer, and by the speed control device can be adjusted to a desired speed;

3, when equipped with the packaging of goods placed on the conveyor belt, sealing parts are automatically sent to the two bags in the operation of sealing tape and into the heating zone, heat sealing block through the belt transmission to the sealing part of the bag, the thin film heating molten soft, then through the cooling zone, the film surface temperature properly decreased then after a knurled wheel (or wheel rolling), so the sealing part on the plastic film sticking and pressing a reticulated pattern (or printed logo), and then by the guide rubber belt and conveyor belt will be sent packing bag sealed, complete sealing operation.

Elida brand functional film sealing machine maintenance:

1, after the use of the machine to deal with dust on the equipment;

2, in the first time after the closure of the temperature control switch is closed to allow the machine to run 3-5 minutes, so that it helps to protect the sealing bag in the heating temperature stay and reduce the service life;

3, ELIDA plastic bag sealing machine every 6 months or so on the drive gear lubrication oil.